|

Axial Ion Path® Reference

- Patented design increases sensor life, accuracy and reliability

- High resistance to poison: Reduced calibration offset error

- Large surface area reference junction eliminates plugging issues

- Eliminates error due to fluctuating pressure

- No exotic gel or polymer electrolyte which may be incompatible with the process

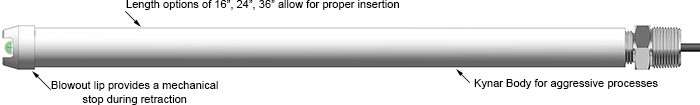

The Model 567 All Plastic Hot Tap Retractable Sensor. If your piping is corrosion resistant plastic, shouldn’t your pH sensor be the same? The Model 567 is specifically designed for use in the most aggressive measurement applications. It is the only “All Plastic” hot tap retractable pH sensor available to the market. The 567 sensor uses a Kynar insertion body thus eliminating the metallic sheath typically used with cartridge style hot tap sensors. Not only can it withstand strong chemicals; the Kynar body provides a great solution in applications that build-up and adhere to metallic parts.

|

Pressure/Temperature Ratings

Sensor

Material |

Installation Type

|

Teflon or Kynar

Compression Fitting |

PEEK Stop Lock

Compression Fitting |

| Kynar (white) |

40 PSIG @ 167°F (75°C) |

100 PSIG @ 167°F (75°C)

35 PSIG @ 212°F (100°C) |

Insertion Depth

The depth that pH / ORP sensor protrudes into the pipeline can greatly affect the measurement. Applications where the sensor tip is recessed can lead to coating and slow response. In high particulate applications abrasion of the electrode can be a concern.

A typical installation goal is to get the sensor tip at least 1/4" (6mm) into the stream. At this depth coating issues lessen and response improves due to flow velocity.

Installation Methods

Isolation Ball-Valve "Hot-Tap" Applications