The Barben Analytical SafeTap II is a retractable or “hot tap” Optical Oxygen Sensor. It is used with the OXYvisor Oxygen Analyzer for in situ sampling methods. Designed for use in liquids and dry or wet gases, the SafeTap II can be manually inserted and retracted from the process line. The SafeTap II provides the capability of in situ installation of a selectable BOSx Oxygen sensor ranges into the process pipe or vessel.

| BOSx Oxygen Sensor Ranges |

| BOS1 Oxygen Range |

0 % to 4.2 % (gas)* |

0 ppb to 1.8 ppm (liquid) |

| BOS2 Oxygen Range |

0 % to 25 % (gas) |

0 ppb to 22 ppm (liquid) |

| BOS3 Oxygen Range |

0 to 300 ppm with 1000 ppm over range (gas) |

* With over-range to 5 % O2

Typical Applications

- Biogas: Compatible with CH4, CO2, H2O, H2S, N2, O2, NH3 & H2; suitable for H2S removal/sweetening and biomethane trace O2 measurement.

- Carbon capture: Measures CO2 and O2 at trace and % levels.

- EOR - Enhanced Oil Recovery: Measures ppb dissolved O2 for seawater injection.

- General replacement: For Trace O2 ppm to % level measurement, replacing E-Chem cells.

- Upgrade E-Chem: Use optical for Trace O2 ppm to % level measurements, where E-Chem drift or fail.

|

|

Advantages

- Resistant to E-Chem poisons (H2S, CO2, H2).

- Accurate measurement regardless of flow rate.

- Unaffected by air or high O2 exposure.

- Accurate in particulate (dirty) streams.

|

Features & Benefits

- Uses optical quench luminescent technology: no cross-sensitivity to CO2, SO2, NH3, and H2S, not affected by high O2 levels and moisture.

- Eliminates sample handling systems in extractive sampling.

- Reduces installation costs, complexity, and maintenance.

- Adjustable sensor insertion length for various pipe diameters.

- Integrated RTD at sensor tip for accurate temperature measurement and compensation.

- Optional pressure transmitter for accurate in-line pressure compensation of O2 measurement.

- T-Handle and safety hook prevent blow-outs and ensure safe operation during insertion and retraction.

- Quick and easy sensor cap replacement.

- Approved for Hazardous Location installations:

- Fiber Optic O2 light energy is certified “op is” (optically inherently safe).

- Integrated RTD suitable for C1D2 or Zone 2.

- Special Exd considerations for RTD in Zone 1.

Principal of Operation

Figure 1 shows the SafeTap II assembly with an optional pressure transmitter (1) for continuous pressure measurement and calibration. The BOS SafeTap II oxygen sensor includes a Pt1000 RTD (5) for Class 1 Div 2 and Zone 2 or an external RTD for Zone 1 and is rated up to 750 psig (51.7 Bar). Tubing ports allow for in situ calibration and 450 psig (31.0 Bar) in retracted mode without removing the sensor.

The Safe-T-Handle (2) enables secure manual insertion/retraction. A security hook (3) prevents unintended retraction, and the 316SS Ball Valve (4) eliminates the need for a secondary isolation valve. Optional 316SS needle valves simplify manual calibration.

The replaceable luminophore window sensor cap (6) allows easy maintenance. The cap can be unscrewed and replaced by hand after retracting the tip through the ball valve (4).

Refer to the SafeTap II Oxygen Sensor Manual for detailed instructions.

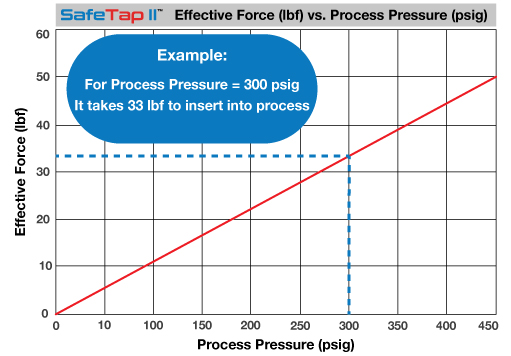

Effective Force vs Process Pressure

The SafeTap II utilizes a 3/8” insertion rod for insertion/retraction. The small diameter rod helps to significantly reduce the force required during normal operation, insertion/retraction or during process upsets. For example, Figure 2, shows the Effective Force (lbf) required to insert the sensor into process with various Process Pressure (psig).

Figure 2

Installation Examples

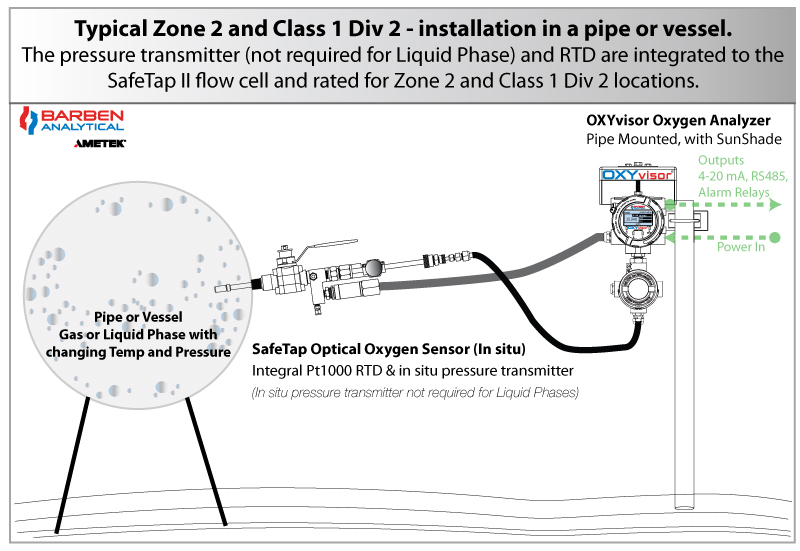

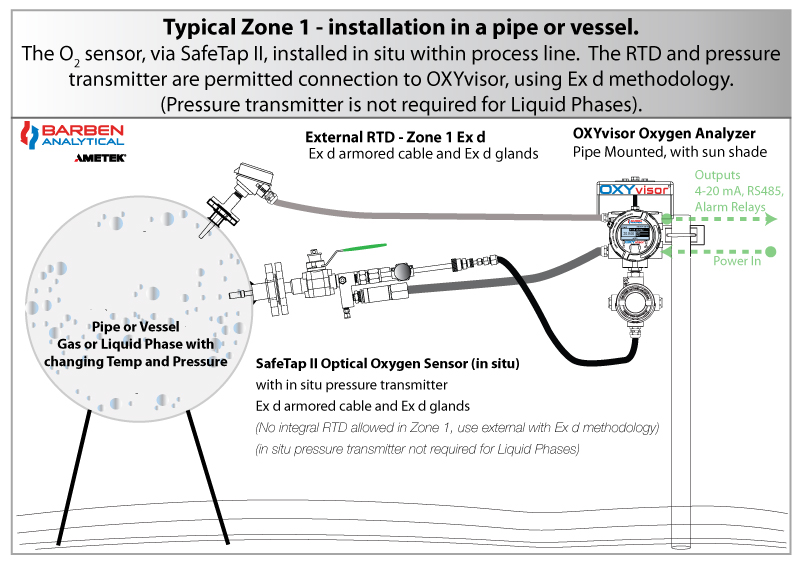

This section references hazardous location installation examples (see Figure 3 and 4) with measurements for liquid or gas phases. The OXYvisor oxygen analyzer with SafeTap II has agency approvals for Zone 1, Zone 2, and Class 1 Div 2 installation locations; see below for listed approval agencies. The SafeTap II is rated up to pressures of 750 psig (51.7 Bar) in normal process operating conditions, and 450 psig (31.0 Bar) during insertion and retraction of the SafeTap II.

OXYvisor Analyzer is shown in both Figure 3 and 4 are mounted in a hazardous location with the pipe mount kit and optional sunshade accessory. The recommended cable length is 5 meters with options to 10 meters (for greater lengths, please consult the factory). For all installation requirements, review the OXYvisor and SafeTap II manuals mentioned in the Standard Documentation section.

Figure 3

Figure 4