|

Axial Ion Path® Reference

- Patented design increases sensor life, accuracy and reliability

- High resistance to poison: Reduced calibration offset error

- Large surface area reference junction eliminates plugging issues

- Eliminates error due to fluctuating pressure

- No exotic gel or polymer electrolyte which may be incompatible with the process

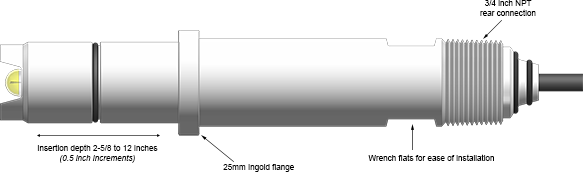

In some in-line applications sensor removal for routine cleaning or calibration becomes difficult due to conduit or cabling. The 551 Quick Change Sensor offers a unique method to extract the sensor through a “Nut Lock” Adapter system. The Nut Lock Adapter threads directly into 1 inch NPT process connections. Sensor length options up to 12 inches allows the sensor to fit through flanges and stand-off piping. The 551 sensor also includes a 3/4 inch rear connection for use in submersible applications.

|

Pressure/Temperature Ratings

Sensor

Material |

Quick Change Nut Lock Adapter Style

|

|

|

Threaded plastic or

metal body with hand nut

|

Threaded metal body

with metal hex nut |

Plastic body with metal hex nut

(flanged or threaded mounting) |

| Kynar (white) |

150 PSIG @ 158°F (70°C)

40 PSIG @ 266°F (130°C) |

300 PSIG @ 176°F (80°C)

40 PSIG @ 266°F (130°C) |

150 PSIG @ 73°F (25°C)

25 PSIG @ 266°F (130°C) |

| Peek (tan) |

150 PSIG @ 158°F (70°C)

40 PSIG @ 266°F (130°C) |

300 PSIG @ 176°F (80°C)

40 PSIG @ 266°F (130°C) |

150 PSIG @ 73°F (25°C)

25 PSIG @ 266°F (130°C) |

Insertion Depth

The depth that pH / ORP sensor protrudes into the pipeline can greatly affect the measurement. Applications where the sensor tip is recessed can lead to coating and slow response. In high particulate applications abrasion of the electrode can be a concern.

A typical installation goal is to get the sensor tip at least 1/4" (6mm) into the stream. At this depth coating issues lessen and response improves due to flow velocity. 546, 551 and 547 sensors offer a variety of insertion depths. Here are some guidelines.

Installation Methods

In-Line Applications (Threaded)

In-Line Flange Applications